BlueMarine³.com in the spotlight

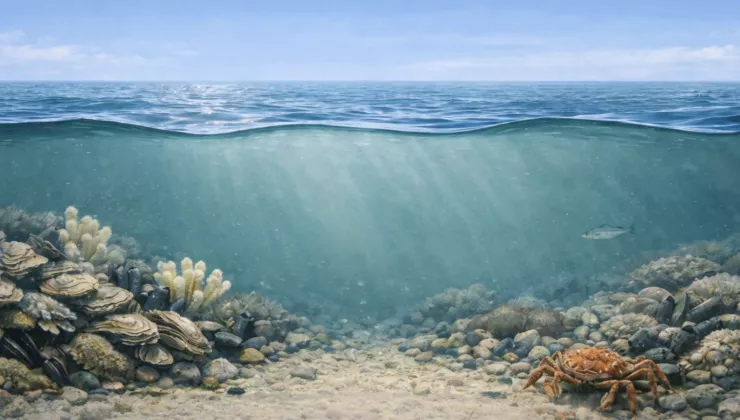

The global aquaculture market is experiencing strong growth, which also increases the demand for breeding material. This generates opportunities for the cultivation of various species of microalgae, as they remain an indispensable fodder for many aquaculture species.

The Flemish company Proviron produces microalgae in in-house developed bioreactors. The microalgae are marketed worldwide and serve mainly as food for the larvae of shrimp, bivalves and sea cucumbers, as well as for rotifers used as feed for sea bream, sea bass, turbot and other fish species.

There are currently 6 commercial products on the market made from Nannochloropsis, Isochrysis, Chaetoceros, Tetraselmis and Thalassiosira. At the Hemiksem production site, Proviron develops new algae species and conducts research to further improve these algae products.

Manipulating the nutritional profile of microalgae

Within the context of the BlueMarine³.Com project, Proviron investigates the performance of three new species of microalgae with high market potential. To this end, they are collaborating with Ghent University to gain insights into the effect of algae on the growth of shrimp and oyster larvae through feeding tests.

The quality and quantity of microalgae is extremely important at all life stages, and different stages have different nutritional requirements. As this depends on the nutritional profile and the size of the microalgae, Proviron is investigating the effect of culture conditions on these parameters.

Automatic feeding unit prototype

Proviron is heavily investing in automation in order to have maximum control over the cultivation conditions and to reduce the production cost of microalgae. The same approach has also been adopted within the project for oyster and shrimp cultivation systems. For this purpose, Proviron has developed a continuous automatic feeding system for microalgae.

The automatic dosing unit uses sensors that utilise the natural light absorption of algae to determine the algae concentration in the tanks. The idea is two-fold: on the one hand, automatic dosing feeds the same amount of algae as is eaten every day, and, on the other hand, this ensures that the shrimp or oysters have the same algae concentration available at any time of the day.

Resaerchers at the Laboratory of Aquaculture & Artemia Reference Center (ARC) of Ghent University are currrently investigating whether oyster and shrimp larvae grow faster and whether less algae are lost.

Live versus dried microalgae

Using freeze-dried algae offers a number of advantages, such as permanent availability, long shelf life, ease of use and consistent quality. For shrimp larvae, feeding tests in the BlueMarine³.Com project have already shown that freeze-dried algae are an excellent alternative.

For oyster larvae, it appears that live algae cannot yet be completely replaced by the freeze-dried alternative. This may be due to the processing process, which may result in a partial loss of the nutritionally important essential fatty acids and antioxidants, or even other components.

Proviron is now looking further into a modified protocol to avoid these problems and is also working on other presentation forms of the algae, such as pastes.

Background

BlueMarine³.Com is a cooperation initiative of various groups of Ghent University: the IOF consortium BLUEGent (Dr. ir. Margriet Drouillon), the Laboratory of Aquaculture & ARC (Prof. Dr. ir. Peter Bossier), the Laboratory of Phycology (Prof. Dr. Olivier De Clerck) and the Laboratory of Environmental Toxicology (Prof. Dr. Colin Janssen), and the following companies: Aquacultuur Oostende, Colruyt Group, DEME, IMAQUA, Proviron and SIOEN. This project is supported by Flanders Innovation & Entrepreneurship (VLAIO).