Are vessels on hydrogen or methanol about to become mainstream?

The CHyPS project focused on hydrogen and methanol, two renewable fuels that make it possible to make shipping fossil-free.

Hydrogen can be made from green electricity, and allows more energy to be stored than is possible in batteries. This is especially the case with hydrogen in liquid form, but this requires very special tanks to store hydrogen at -253°C.

When the energy density of (liquid) hydrogen is insufficient, methanol is an alternative. Methanol is the simplest hydrogen carrier that is liquid at atmospheric conditions. This benefits both the energy density and the ease of integrating tanks into ships, or providing a retrofit.

Both fuels are very different from diesel and its relatives, not only in terms of storage but also in terms of use in engines. Large engines such as those used in shipping are today largely diesel engines, and new technology is needed to operate such engines on hydrogen or methanol.

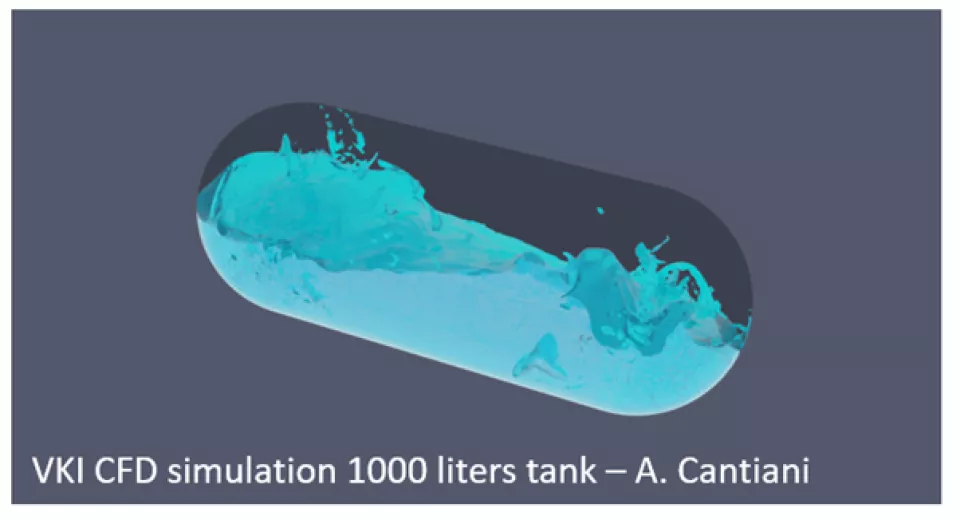

For such large engines and large tanks of liquid hydrogen, numerical models are a must in the development process, given the enormous costs of performing measurements on them.

Partners

The Sustainable Thermo-Fluid Energy Systems (STFES) research group at Ghent University and the von Karman Institute for Fluid Dynamics (VKI) have joined forces in the CHyPS project to provide an answer to the above challenges.

The UGent-STFES group, which specialises in combustion engines and renewable fuels, has developed several models that can calculate the combustion of hydrogen and methanol in ship engines.

VKI has a lot of expertise in dealing with liquid hydrogen thanks to its activities in space travel, and has developed models to predict the behavior of liquid hydrogen in tanks.

Engine and tank types and the test data were obtained from members of the industrial advisory board. This included ship owners (Herbosch-Kiere, DEME, Jan De Nul, GEOxyz, Victrol), engine manufacturers and engineering companies (Anglo Belgian Corporation, Van Wingen, Multi Engineering), and government institutions and research institutes (Vlaamse Waterweg, WaterstofNet, ILVO Marien).

In addition to several test cases, many discussions were held with the advisory board and brainstorms were organised around possible valorisation of the simulation tools. Both UGent-STFES and VKI performed high-quality scientific research and were able to publish their developments of these tools in leading international journals and present them at international conferences.

Valorisation

However, there are currently few opportunities in Flanders to valorise the tools: apart from Anglo Belgian Corporation (with whom the Ghent University group already has ongoing projects), there are no ship engine manufacturers, and there is no production of tanks for liquid hydrogen.

The ship owners, who are present in Flanders in large numbers, are therefore dependent on the supply of tanks by international companies in the field of renewable fuels. This supply is still very limited, and it remains uncertain which fuels will penetrate the market.

The greatest opportunity therefore seems to lie in the use of the tools to generate data that can help with the choice of fuel and investment decisions.

Background

CHyPS is an intercluster project facilitated by VIL, the official Flemish spearhead cluster for logistics, and Blue Cluster. The project receives financial support from VLAIO (Flanders Innovation & Entrepreneurship).